How can I tell if my battery needs to be replaced?

You should replace the battery if one or more of the following conditions occur:

- If there is a .05 (sometimes expressed as 50 “points”) or more difference in the specific gravity reading between the highest and lowest cells of a flooded battery after charge. This means the flooded battery you are testing has a weak or dead cell(s).

- If the battery will not recharge to a 75% or more state-of-charge level. You may notice your charger “timing out” when it was never used to when the battery was new.

- In an automotive battery with a built-in hydrometer that still does not indicate “good” after charge, the battery should be replaced (usually, the hydrometer will show green or blue, representing 65% state-of-charge or better if the battery is good).

- If a digital voltmeter indicates 0 volts on a battery that you know has been properly charged, you have a broken connector, or an open or short-circuited cell, you should replace the battery.

- If a digital voltmeter indicates 10.45 to 10.65 volts on a battery you know has been properly charged, the battery probably has a shorted or dead cell.

- If the battery is fully charged, you can test the capacity of the battery by applying a known load and measuring the time it takes to discharge the battery to 1.75 volts per cell (5.25 volts for a 6-volt battery – 10.5 volts for a 12-volt).

- If the battery fails to deliver at least 50% of its rated capacity - at the applied load - before reaching 1.75vpc, it should be replaced.

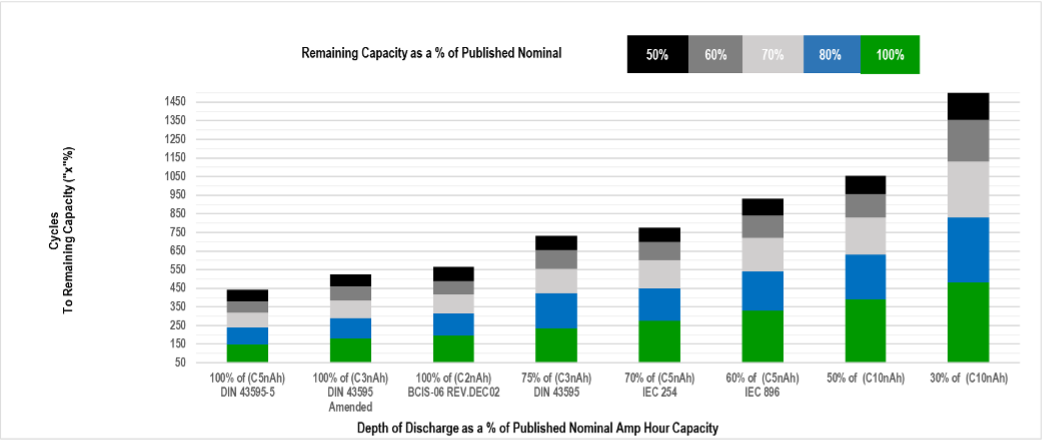

Note: Different types of batteries use test procedures that allow different end-of-life criteria.

For example:

Battery Council International BCIS section 6 Rev. DEC02 states that the measurement of the end-of-life cycle performance of a battery is defined as the point at which the battery will not deliver at least 50% of the manufacturer's rated capacity when discharged at the 2-hour rate. A golf cart battery would not be determined to be at its end of life until it could maintain at least 5.25 volts during a 40-minute discharge at 75 amps.

Depending on your application, batteries tested and proven to perform above 50% of their original capacity may not meet your operational needs even though they pass the industry good/bad test standard.

Discover thinks that in most commercial applications where productivity is critical, batteries that do not reach 60%-70% of original capacity should be replaced. If the battery passes the load test, recharge it as soon as possible to restore it to peak performance and prevent lead sulfation. Always consider the temperature when making your evaluation, and make sure that the batteries have been adequately charged before testing.

Figure 6 illustrates eight different Industry Cycle Life Test Standards with Remaining Capacities.

Figure 6 – Cycle Life Testing Standards at various Rates and to various remaining capacities